Mud circulation system:

Mud circulation system:

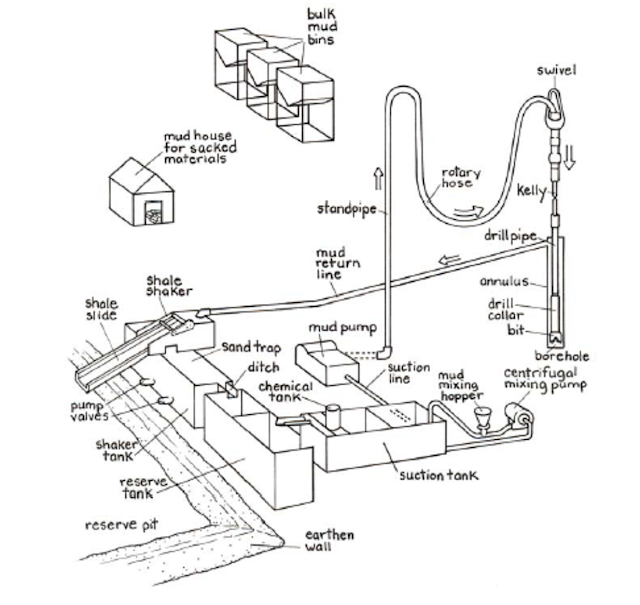

Mud

circulating system developed during the end of 1940s, after high pressure pumps

and jet bits became available. Modern mud system is a combination of various

systems all for the purpose of circulating mud and to clean it.

Mud Circulating System Components:

·

Mud return line

A trough

or pipe, placed between the surface connections at the well bore and the shale

shaker.

·

shale shaker

A

series of trays with sieves or screens that vibrate to remove cuttings from

circulating fluid; openings size are selected to match the size of the solids

expected.

·

Desander

A

centrifugal device for removing sand from; It may be operated mechanically or

by a fast-moving stream of fluid inside a special cone-shaped vessel, in which

case it is sometimes called a hydrocyclone.

·

Desilter

A

centrifugal device, similar to a desander, used to remove very fine particles,

or silt. To keeps the amount of solids in the fluid to the lowest possible

level.

·

Degaser

The

equipment used to remove unwanted gas from a liquid, especially from drilling

fluid.

·

Mud-Gas Separator

A

device that remove gas from the mud coming out of a well when a kick is being

circulated out.

·

Mud Tanks

(pits)

A

series of open tanks usually made of steel plates, through which the drilling

mud is cycled . Additives are mixed with the mud in the pit, and well . They

are also called shaker pits, and suction pits, depending on their main purpose.

·

Mud Pumps

A

large reciprocating pump used to circulate mud on a drilling rig.

·

Chock Manifold

The

arrangement of piping and special valves, called chokes, through which drilling

mud is circulated when the blowout preventers are closed to control the

pressures encountered during a kick.

·

Mud gun

Is typically used

to mix the mud mixture in the rig tanks (see Figure).

This is done to maintain a homogenous mix and ensure an

even distribution of mud components. In carrying out this function, the outlet

pressure can become high enough that the gun might become unmanageable by

workers.

Mud Circulating Systems:

Circulation

of drilling mud begins from the mud pits, with suction lines leading to the mud

pumps (figures). Mud pumps send the mud through the rotary hose into the

swivel, down through the drill stem, and out through the bit. The mud returns

to the surface through the annulus of the borehole, then through the mud return

line back into the mud pits. The mud is made up and conditioned in the surface

system, using various materials and auxiliary equipment.

The

mud pump is the primary component of any system using a liquid as the

circulating fluid. It furnishes the pressure for sending the fluid through the

system. The swivel permits the drill stem to be raised or lowered while

circulating and rotating. The drill stem, made up of Kelly, drill pipe, and

drill collars, rotates the bit, furnishes weight for drilling, and provides the

con dui through which fluid flows to the bit. Drilling fluid passes through the

bit, out the nozzles, and up through the annulus, which is the space between

the drill stem and the wall of the well. Fluid returning to the surface through

the annulus carries with it the cuttings made by the bit. When the fluid

reaches the surface, it flows into the mud pits through a mud return line,

after having rock cuttings, sand, and shale separated from it by devices such

as shale shakers, desanders, desilters, and centrifuges.

A

system for pumping drilling mud typically operates at high pressure of up to

34,000 kilopascals (4,930 pounds/square inch). To ensure that a component of

the system does not fail, all parts of the system must be rated at least equal

to the maximum working pressure of the pump. This is also known as the

“allowable rated working pressure”.

Typically, this is shown on a metal plate

affixed to the pump.

Mud circulation system:

Reviewed by mohammed omar oun

on

November 27, 2019

Rating:

Reviewed by mohammed omar oun

on

November 27, 2019

Rating:

Reviewed by mohammed omar oun

on

November 27, 2019

Rating:

Reviewed by mohammed omar oun

on

November 27, 2019

Rating:

No comments: